Governmental Projects for the Creation of a Hydrogen Society

- Home

-

What Kind of Energy is Hydrogen?

【Basic】 - Governmental Projects for the Creation of a Hydrogen Society【Trends】

※go to the bottom of the page

Contact Information

Climate Change Projects Office,Climate Change Policy Division,Global Environment Bureau,Ministry of the Environment

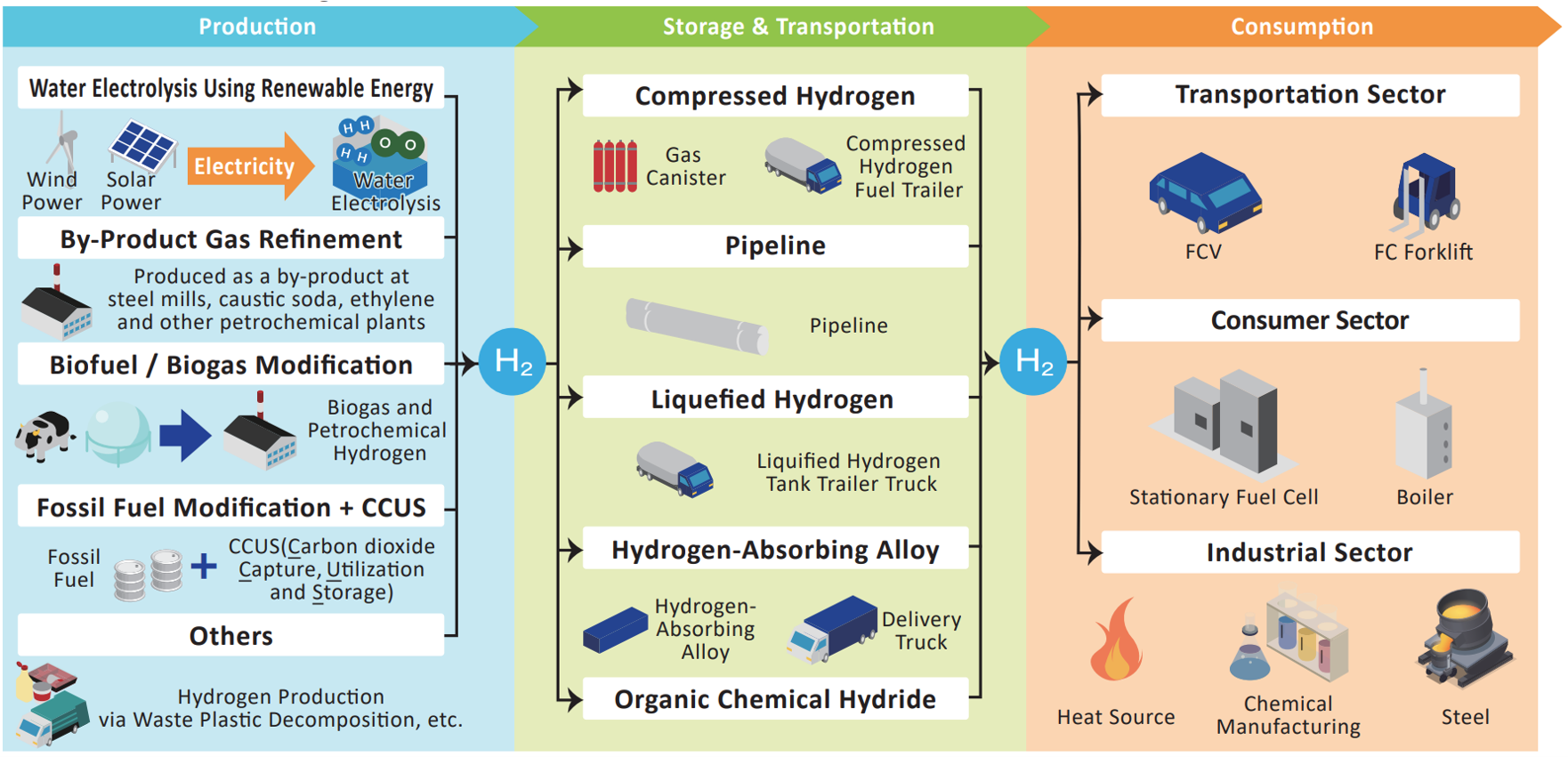

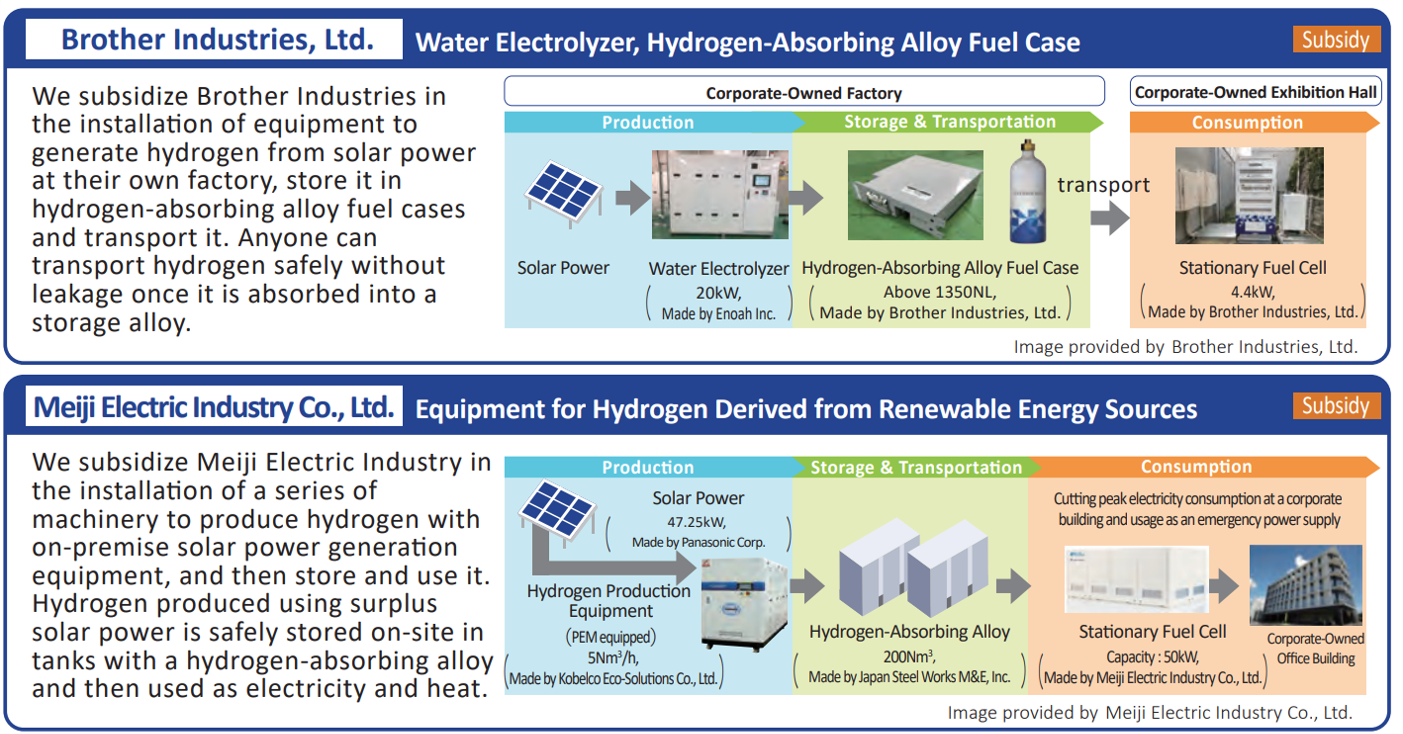

The creation of a hydrogen supply chain comprised of production, storage & transportation and consumption stages is essential for utilizing hydrogen as an energy source. Each of these three stages is characterized by the use of various technologies.

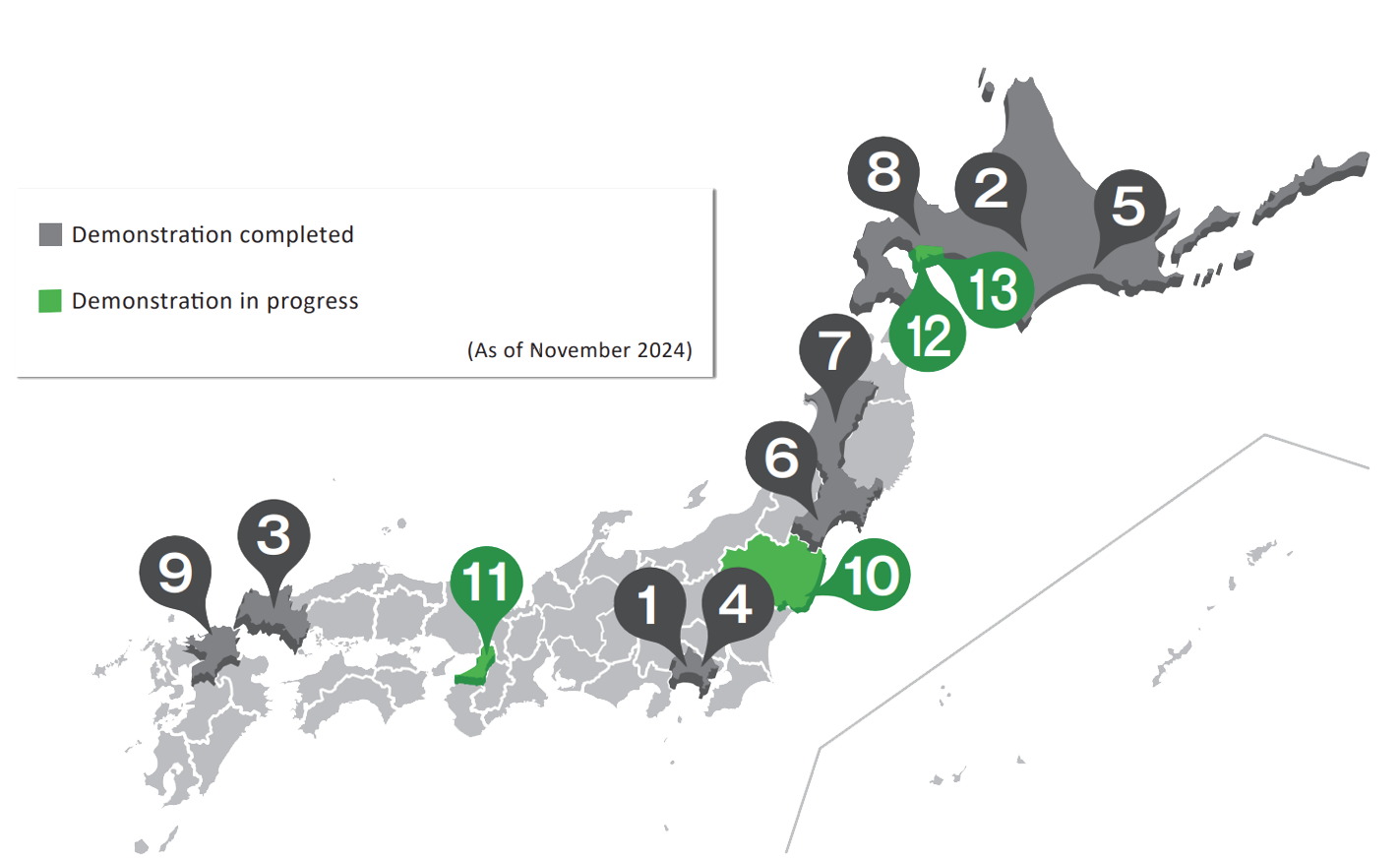

The MOE promotes decarbonization by engaging in projects that demonstrate how hydrogen supply chains can be created utilizing local resources.

-

04

Primary Partner:Showa Denko K.K.

Low-Carbon Hydrogen Demonstration Project of Waste Plastics Regional Circular Model

-

05

Primary Partner:Toshiba Energy Systems &

Expanding the Use of Hydrogen Produced from a Small Hydropower Plant and Establishing a Hydrogen Utilization Model Suitable for the Local Characteristics of Hokkaido

Solutions Corp.

-

07

Primary Partner:NTT DATA INSTITUTE OF MANAGEMENTCONSULTING, Inc.

Project to Demonstrate the Production of Hydrogen from Electrolysis Using Wind Power, as well as the Supply and Use of Hydrogen Mixed with Natural Gas

-

08

Primary Partner:TAISEI Corp.

Project to Demonstrate a Low-Pressure Hydrogen Delivery System to Promote Hydrogen Use in Buildings and City Infrastructure

-

09

Primary Partner:Kitakyushu Power Co., Ltd.

Project to Demonstrate Green Hydrogen Production and Supply Using Local Renewable Energy in Kitakyushu City

-

10

Primary Partner:OBAYASHI Corp.

Project to Construct and Demonstrate a Low-Cost Renewable Hydrogen Supply Chain Using an Operation Optimization System

-

11

Primary Partner:OSAKA GAS Co., Ltd.

Hydrogen Supply Chain Demonstration Project of Methanation Utilizing Renewable Hydrogen and Food Waste Biogas in Urban Areas

-

13

Primary Partner:SPARX Green Energy & Technology Co., Ltd

Turning Hokkaido into a Hydrogen Island, a Large-Scale Renewable Hydrogen Supply Chain Demonstration Project That Does Not Depend on the Power System

-

TOYOTA MOTOR Corp.(Yokohama City and Kawasaki City, Kanagawa Prefecture, FY2015-FY2020) [PDF 111KB] PDF

Produce hydrogen from wind power plant, and deliver it by simplified hydrogen fueling vehicles to use it for FC forklifts at local warehouses, factories or markets.

-

Produce hydrogen from livestock manure and transport it in curdles to use it for stationary fuel cells in the region.

-

Tokuyama Corp.(Shunan City and Shimonoseki City, Yamaguchi Prefecture, FY2015-FY2021) [PDF 155KB] PDF

Collect unused high purity byproduct hydrogen from caustic soda plants, compress and liquefy it to transport to utilize for stationary fuel cells or FCVs in the region.

-

Collect and purify hydrogen produced from waste plastics, transfer it through pipelines and utilize it at business facilities or in stationary fuel cells.

-

Produce hydrogen from a small hydropower plant, transport it via compressed hydrogen tube-trailers or curdles and utilize it for stationary fuel cells and FCVs in the dairy facilities and heated swimming pool in the region.

-

Store hydrogen that is produced from solar power in metal hydride, and transport it using the existing logistics to utilize at stationary fuel cells at households and a childcare center.

-

Produce hydrogen from wind power and mix it with a high calorific simulated gas similar to municipal natural gas, and transport it via pipelines to utilize it for commercial gas devices.

-

Produce hydrogen from wind power, store and transport it using on-vehicle and stationary metal hydride tanks and hydrogen delivery vehicles to utilize it for stationary fuel cells at a hot spring facility.

-

Hydrogen is produced from wind power and solar power in this project. The hydrogen is transported in curdles and then utilized for FC forklifts and FCVs in neighboring regions.

-

Hydrogen is produced at Fukushima Hydrogen Energy Research Field in this project. The hydrogen is transported by curdles and compressed hydrogen tube trailers, and then utilized for stationary fuel cells and FCVs in the neighborhood.

-

Produce methane by methanation using hydrogen from renewable energy sources and biogas produced by fermentation of food waste, transport through pipeline and utilize in city gas consuming appliances.

-

Utilizing an existing LP gas delivery network, hydrogen produced from wind power is delivered at low pressure in cylindrical tanks which contain a hydrogen absorbing alloy.

The hydrogen is used in residential fuel cells, hydrogen boilers in small restaurants and lodging facilities, and hydrogen gas cutters in metal processing plants. -

SPARX Green Energy & Technology Co., Ltd. (Tomakomai City, Hokkaido, Adopted in 2023) [PDF 154KB] PDF

Hydrogen produced from solar and waste-to-energy power will be transported via high-pressure tank trailer trucks, which also serve as hydrogen storage, to municipal facilities and nearby businesses for use in stationary fuel cells, boilers, and stoves.

Regional Low-Carbon Hydrogen Supply Chain Projects

Demonstration Project for a Low-Cost Hydrogen Supply Model Utilizing Renewable Energy

Demonstration Project for a Low-Cost Hydrogen Supply Model Utilizing Existing Infrastructure

The MOE supports businesses in introducing various hydrogen-related equipment for producing, storing, transporting and consuming hydrogen.

The MOE is subsidizing businesses to develop and incorporate applications, particularly in the transportation sector.

FC Forklift Subsidy

Photo compliments of TOYOTA INDUSTRIES Corp.

R&D support for a FC forklift and the potential of reduced costs and improvement of energy efficiency and drability, leading to commercialization in 2016.

These forklifts are not only environmentally friendry, but also boasts a convenient, quick refuelling time of approx. three minutes.

Multipurpose FCV Subsidy

Photo compliments of TOYOTA MOTOR Corp.

In 2021, Kumamoto Red Cross Hospital and Toyota began the world's first demonstration of the use of FC medical vehicles.

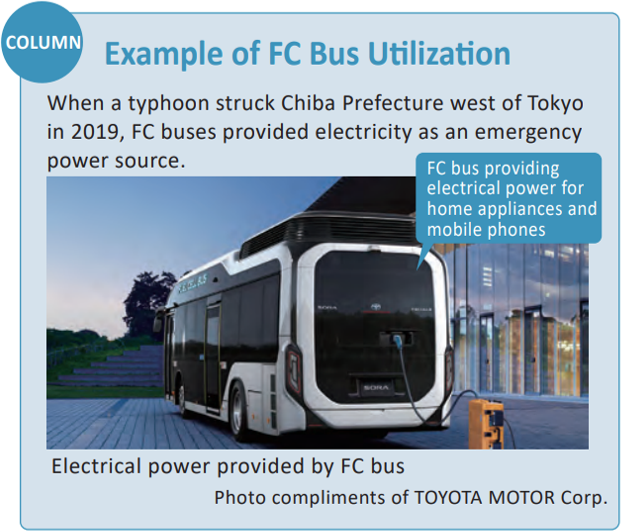

FC Bus Subsidy

R&D support for FC buses to improve power performance, reliability and durability leading to commercialization in 2017.

It supports the implementation of FC buses, which boast both environmental friendliness and comfort.

Photo compliments of TOYOTA MOTOR Corp.

MOBILE AND INFRASTRUCTURAL EXAMPLES FOR THE CREATION OF A HYDROGEN SOCIETY

-

Fuel Cell Vehicles (FCV)

State of FCV Introduction in Japan [PDF 231KB]PDF

-

Commercial Hydrogen Stations

State of Commercial Hydrogen Stations Operating in Japan [PDF 157KB]PDF

-

Fuel Cell Forklifts (FCFL)

State of Subsidy Projects to Introduce FCFL [PDF 198KB]PDF

Contact Information

Climate Change Projects Office,Climate Change Policy Division,Global Environment Bureau,Ministry of the Environment