Health & Chemicals

Mercury-related technologies and facilities in Japan

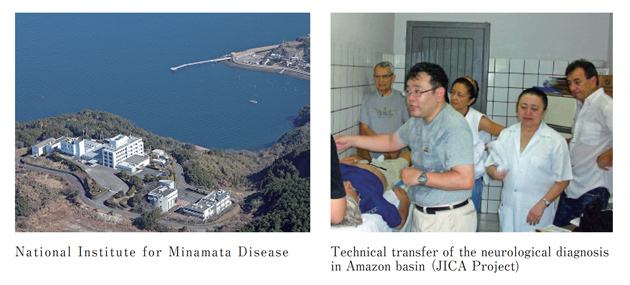

National Institute for Minamata Disease

The National Institute for Minamata Disease (NIMD) is the only organization in the world that is specialized in comprehensive mercury research, and it has accumulated significant amount of mercury-related information as well as numbers of analytical technologies and research outcomes.

Minamata disease was caused by the environmental pollution due to methylmercury resulting from the lack of environmental awareness in the course of giving priority to economic growth. As the WHO Collaborating Center for studies on mercury, the NIMD conducts dissemination of information on Minamata disease via its information center, the Minamata Disease Archives, and the training programs it provides, hoping that such information will help people around the world learn from Japan's experience.

The NIMD is also engaged in surveys and research to assess the exposure to mercury and to prevent its impact in the countries suffering the environmental pollution by mercury.

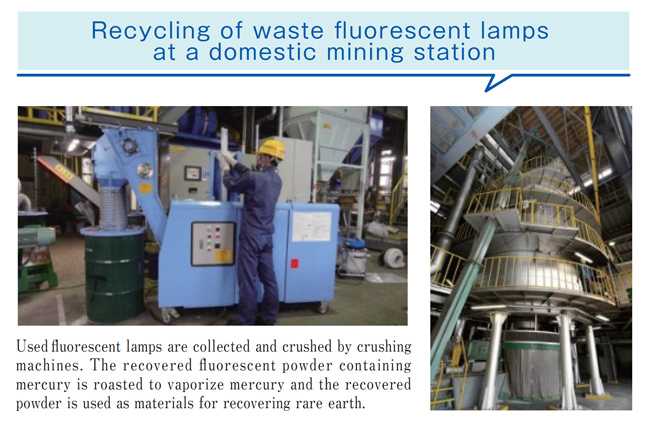

Recovery of Mercury from mercury-added product wastes

In Japan, mercury-added product wastes are collected through voluntary collection by manufacturers or through the sorted waste collection by municipalities and then treated in an environmentally sound manner. Most of the waste containing mercury is recycled at a former mining facility in Hokkaido. While primary mercury mining does not exist in Japan, the recovered mercury is used for necessary purposes.

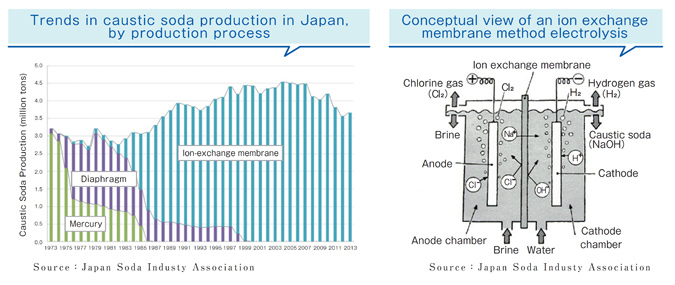

Reduction of mercury use in manufacturing processes

Mercury is used in various manufacturing processes, e.g. chlor-alkali, vinyl chloride monomer and acetaldehyde. Japan has converted all of these manufacturing processes into mercury-free methods. Caustic soda can be produced by the ion exchange membrane process, diaphragm process or mercury process. During the post-war economic growth period in Japan, caustic soda was produced primarily by the mercury process, and the production of the caustic soda by this process accounted for more than half of the mercury use in Japan from the 1960s until the mid-1970s. By 1986, the mercury process was completely withdrawn for the production of caustic soda in Japan. As a result of the investment in technology development by the caustic soda industry, the ion exchange membrane process has become a principal technology of Japan. Since 1999, the ion exchange membrane process has been used for the entire production of caustic soda in Japan.