Chapter I -1 :Quality of the Environment in Japan 1998

Chapter I: Towards a Socio-economic System with Environmentally Sound Material Cycles

1. Applying circulation to waste recycling

The current situation and problems regarding waste disposal

A "one-way" society in material balance terms

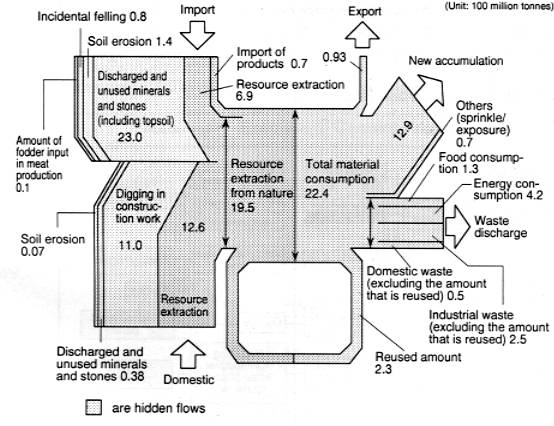

In looking at the use of materials in Japan in terms of material balance, in 1996 the amount of resources used for economic activities amounted to 2.01 billion tons. The quantity recycled was 0.23 billion tons, and the recycling rate was a mere 10%.

The material flow within the country has low circularity. It is predominantly characterized by a one-way flow from acquisition of resources to the final disposal of products. The accumulation of the material balance also occurs with materials from civil engineering and construction projects, and such materials constitute a huge quantity of waste after their durable years have passed. Thus reinforcing recycling systems for this category of materials now will lead to a reduction of environmental load in the future.

Material Balance in Japan (1996)

Note: Due to water absorption, the total amount of production is larger than the total amount of material use.

Source: Calculated by the Environment Agency from various statistics

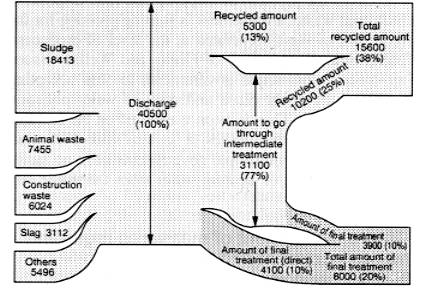

Problem of industrial waste disposal

While the quantity of industrial waste is increasing and the constituent parts of this waste are becoming more varied, the final disposal of toxic waste has become widespread. At the same time problems have arisen such as the inappropriate treatment and reclamation of wastes and the mis-management of final disposal sites, and fear is rising among local people living in the vicinity of such facilities as to environmental damage. Concern exists regarding the pollution of ground water and soil among other things.

The problem of industrial waste disposal tends to be seen as the problem and responsibility of the waste disposal business, but in fact the majority of the problems are caused by illegal dumping and by the inappropriate treatment of wastes by those who produce the wastes yet wish to avoid the cost of disposal. Therefore, the key to the solution of this problem is to include the disposal cost in the expenses of corporate activities and to make sure that the cost is borne appropriately within the economic society through the market mechanism (internalization).

Flow Chart of Industrial Waste Treatment (1994)

Source: Compiled by the Environment Agency from documents of the Ministry of Health and Welfare

Waste disposal and the dioxin problem

In recent years environmental pollution by dioxin emission from such facilities as waste incineration plants has become a serious problem nationwide. It is estimated that over 90% of dioxin emission derives from the process of waste incineration, which is the most common intermediate processing method in waste disposal. Thus it is necessary to improve incineration methods in order to ensure proper waste treatment. New disposal technologies are currently being developed.

The status of final disposal

Given the problem of inappropriate final disposal of industrial waste, a movement is starting pressing for the reduction of waste generated at the level of producers. Meanwhile, the Ministry of Health and Welfare issued an order to municipal governments to stop accepting waste which might cause underground water pollution due to seepage. This decision was based on the fact that 28% of final disposal sites of general (non-industrial) waste owned by municipal governments have no facilities for blocking or treating water from the waste disposal process.

The reinforcement of measures regarding waste treatment and recycling

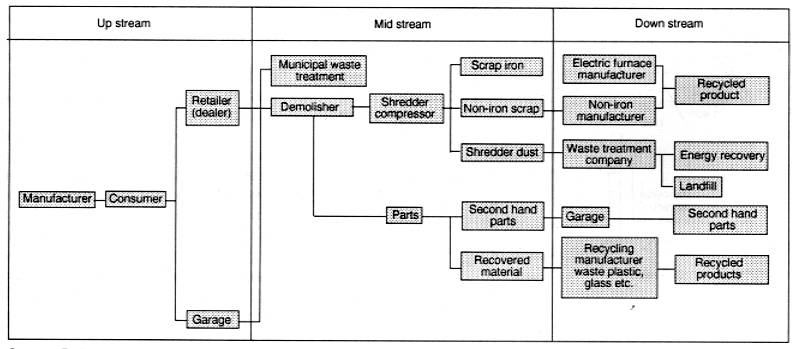

Reinforcement of regulations regarding the final disposal of shredder dust

Since April 1995, it has been made obligatory to treat shredder dust in managing-type final disposal sites. This was decided because environmental damage such as ground water pollution caused by toxic substances buried at stable-type disposal facilities had become a serious problem.

Revision of the Waste Disposal Law

In order to recover public confidence regarding the various problems that have arisen in the waste disposal field, and to ensure appropriate methods of waste treatment, the Waste Disposal Law was amended in June 1997. Amendments focused on the following three points: (1) promotion of waste reduction and recycling; (2) improvement of liability and safety concerning waste treatment; and (3) reinforcement of responsibility on the part of waste producers (as a countermeasure against illegal waste dumping).

Reinforcement of regulations regarding dioxin

Dioxins have become a major social problem. In order to tighten dioxin-related regulations, the Air Pollution Control Law Enforcement Ordinance was partially amended, as a result of which, dioxin substances are now classified as pollutants. Pollutant emission limits are established for waste disposal facilities such as incineration plants. Partial amendments were also made to the Waste Disposal Act Enforcement Ordinance, and structure and maintenance standards for disposal facilities such as treatment plants for exhausted gases were reinforced.

Regulation reinforcement and disposal/recycling costs

The tighter the regulations become, and the more forcefully efficient disposal is demanded to protect the surrounding environment, the higher the costs of disposal treatment becomes. The fact that a huge amount of cost is required for proper waste treatment is thought to be an incentive to review and improve the behavior of businesses and industries which produce waste. It is expected that awareness of the cost on the part of waste producers will encourage the flow of appropriate payments to the waste disposal business. This will also help establish the status of the waste disposal business as a "minor industry," which will contribute to forming an industrial system with sound material cycles.

Flow Chart of Auto mobile Recycling

Source: Environment Agency

Creation of circularity: the challenges that must be overcome before achieving a socio-economic system with environmentally sound material cycles

There are some new attempts to create and expand a circular system such as the establishment of a new system for recycling electric appliances by waste treatment businesses. Various other recycling efforts are being undertaken by industry and local communities. This section of the report will be focusing on several examples of such attempts that are thought to be important. In some cases collaboration between the public and the government, and also collaboration between an expanded range of parties has been involved.

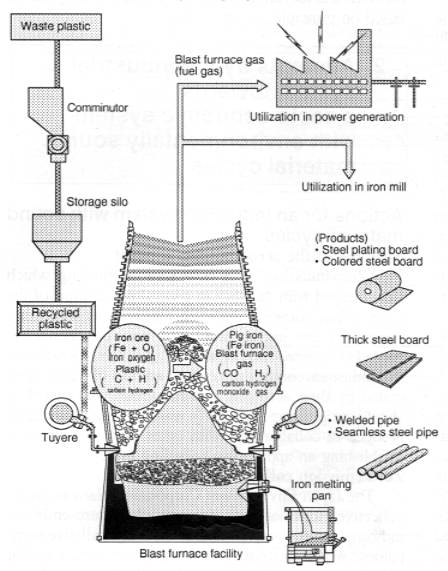

Blast Furnace Recycling System of Waste Plastic

Source: Compiled by the Environment Agency by document of NKK.

Waste recycling within mainstream industries

(1) The steel industry

In the steel manufacture process, the steel industry has started trying to use waste plastic instead of coke as a reducing agent of steel in blast furnaces.

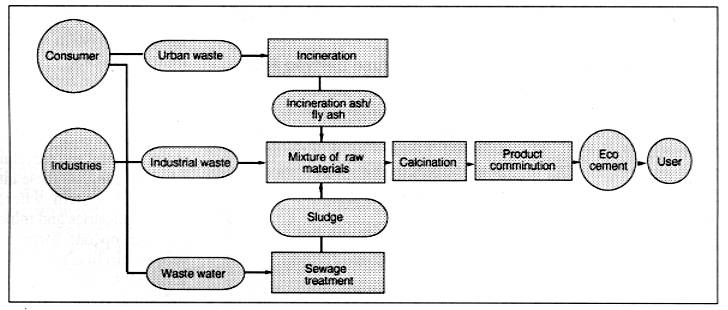

(2) The cement industry

In the cement industry, which by its nature can utilize a wide range of raw materials and fuels, coal residue from thermal power stations and many other industrial wastes such as used tires and waste plastic are coming to be utilized as raw materials or fuels.

It is hoped that there will be more initiatives similar to the two mentioned above, i.e. the large scale utilization of wastes (which otherwise would be buried under the ground at the final stage of disposal) as raw materials or fuels. This would reduce the environmental load caused by both the processes of waste disposal and the processes of natural resource extraction.

Example of Cement Production Process Using Waste

Source: Compiled by the Environment Agency

New initiatives in regional society

The disposal of industrial wastes is carried out in various forms, including disposal by municipal governments. In recent years many tasks have arisen regarding the industrial waste disposal process. These include the improvement of incineration methods as a countermeasure to the dioxin problem, and the intensification and expansion of disposal facilities. The aim of such measures has been to improve appropriate waste treatment as a final disposal solution. It is becoming more necessary to carry out the various tasks relating to waste disposal on a level greater than that of individual municipal authorities.

For the purpose of promoting improvements in disposal technologies and the recycling of industrial wastes, it is an essential precondition to secure the appropriate widespread distribution of waste and recycled resources, and recycled goods, in order to guarantee expanded availability and the convenient procurement of raw materials thereby establishing a market. Also, it is necessary and useful to ensure a collaborative relationship between government and the private sector when it comes to promoting high-tech and safe disposal measures of toxic wastes as well as promoting the recycling of heavy metals.

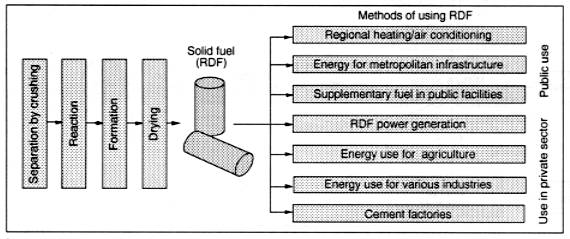

(1)RDF (Refuse Derived Fuel)

RDF is attracting attention as one important recycling method for kitchen waste and waste plastic. With RDF, more efficient heat recovery from wastes becomes possible. RDF also contributes to the reduction of dioxin emissions by more properly managing combustion. After much consideration of the benefits that derive from economic efficiency and from environmental protection, some local governments are already starting to introduce the RDF technology and efficiently utilize RDF technology in cooperation with the private sector. This is occurring, for example, with the cement industry.

Example of Manufacturing Process of Refuse Derived Fuel

Source: Compiled by the Environment Agency

(2) Improvement of waste treatment technologies: the introduction of new methods such as gasification and fusion

In order to improve the combustion process as a countermeasure to the dioxin problem and also to reduce the amount of ashes resulting from the waste incineration process, new technologies such as waste gasification and fusion are being introduced and existing waste treatment systems are beginning to change. With the method of gasification and fusion, wastes are first subject to thermal dissolution yielding pyrolysis gas and inorganic substances including fixed carbon. Using the combustion heat of the gas and fixed carbon the inorganic substances are then solved and fused.

Towards the formation of a socio-economic system with environmentally sound material cycles

In order to most effectively include recycling in the process of waste treatment, it is necessary to investigate more advanced treatment methods and more systematic ways of recycling. A wide range of perspectives, from citizens, companies etc., will be helpful. Much can be learned from countries such as Germany when it comes to the proper treatment of toxic wastes and efficient and economical methods of waste disposal and recycling using the market forces principle as motivator. Nationwide discussions are also necessary to integrate such disposal methods and recycling systems to create a society that is based on principles of circularity.